Enquire about the IMS Series

Receive advice about product specifications and find the right Boschung vehicle and equipment for your needs.

Sweeping Revolutionized. The Urban-Sweeper S2.0 MAX is now available. Discover more

Close

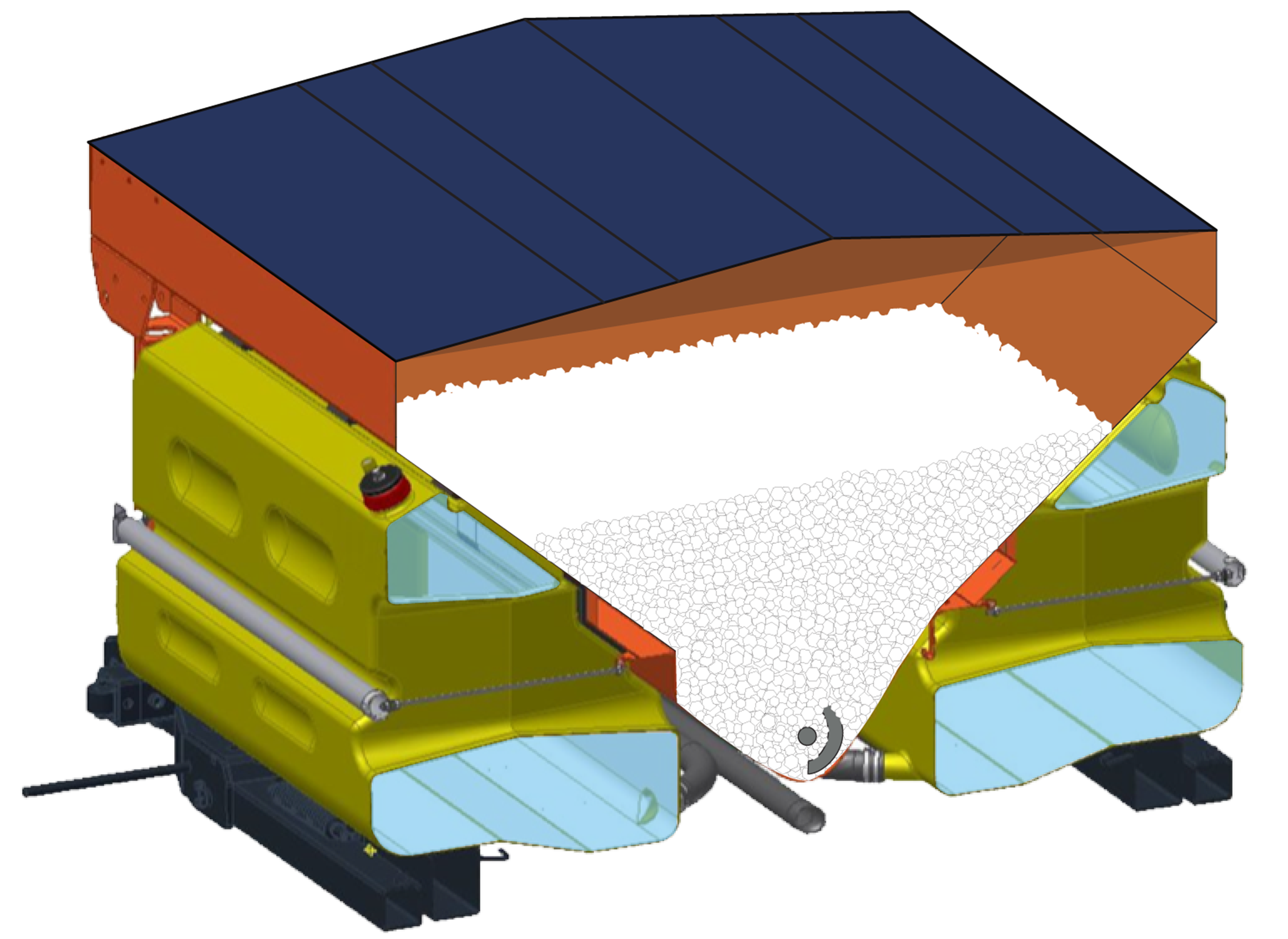

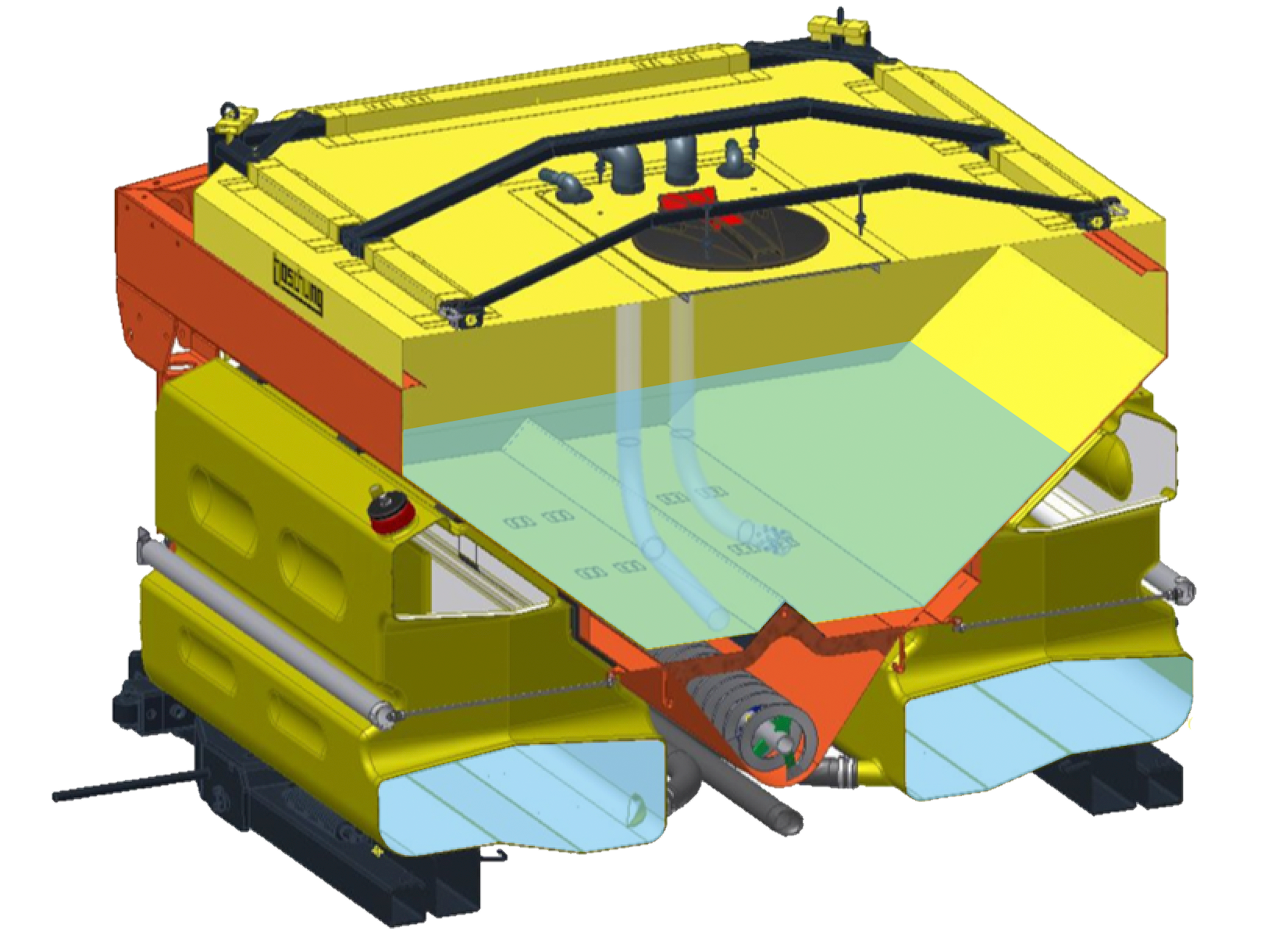

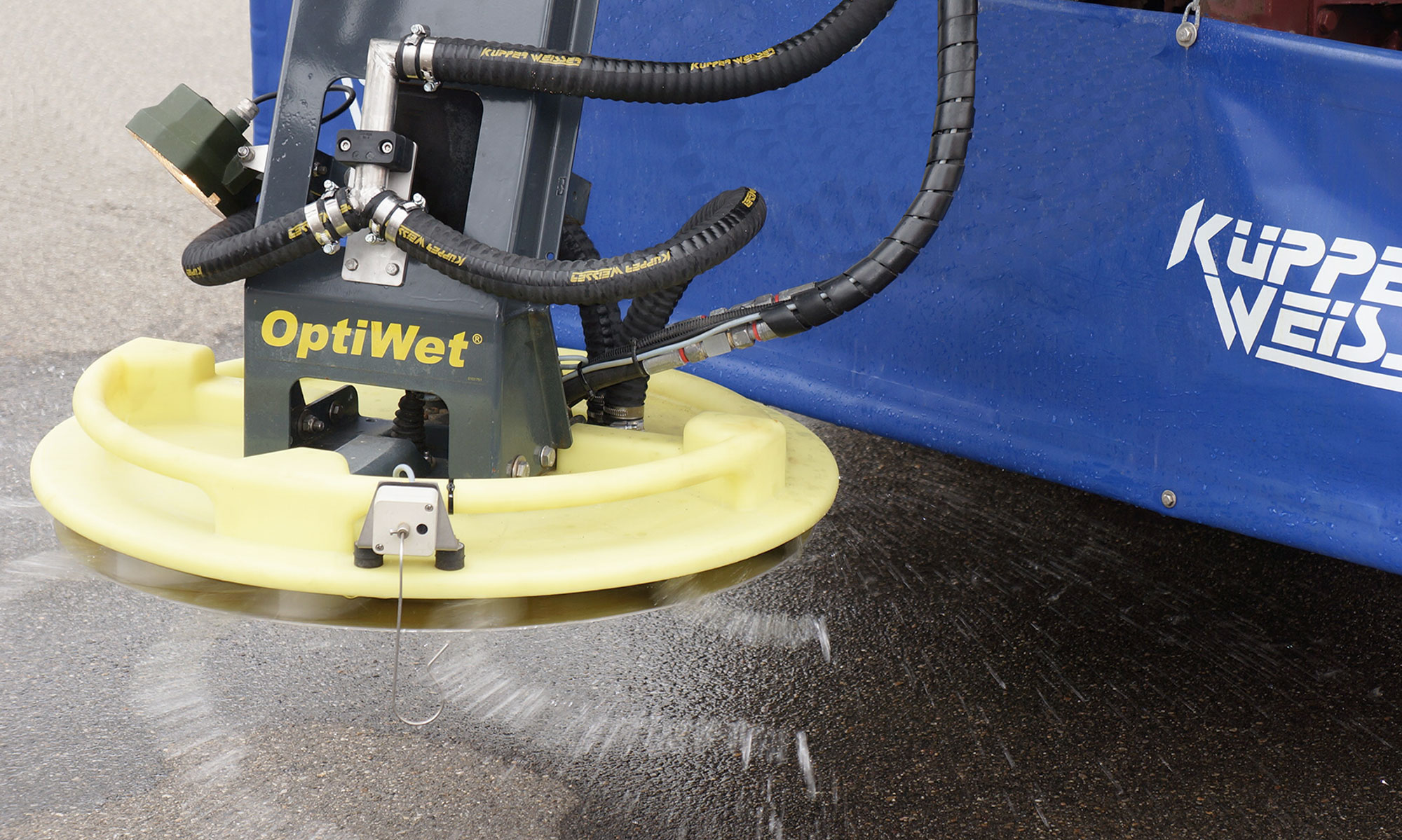

Intelligence and automation for flawless precision and sustainability, the IMS Series uses innovative components and state-of-the-art technologies for the maximum spreading accuracy. One clever science, the OptiWet® distribution system hides an array of engineering masterpieces for the perfect mixture and spreading pattern at any speed. Only when the perfect amount of salt is spread in the perfect pattern can de-icing become sustainable and eco-friendly.

Millions of tons of salt are used each year for the de-icing operations of traffic surfaces. Such quantities of salt not only take a huge part of your winter maintenance budget, it also contaminates the ground water and damages the environment. IMS offers the precision of a homogenous mixture of salt and brine without saturation and automatically adjusted to the situation, the FS-Adaptive®.

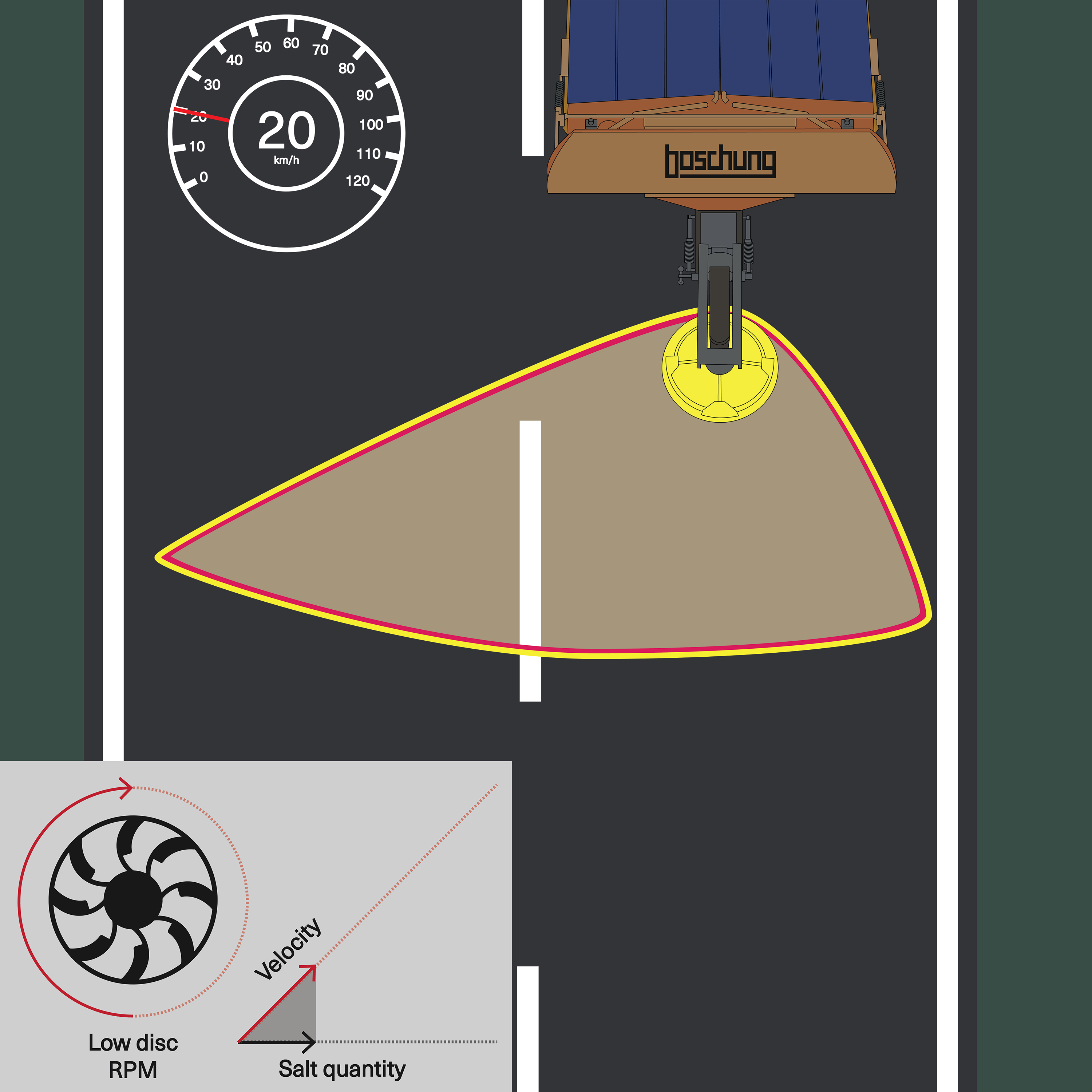

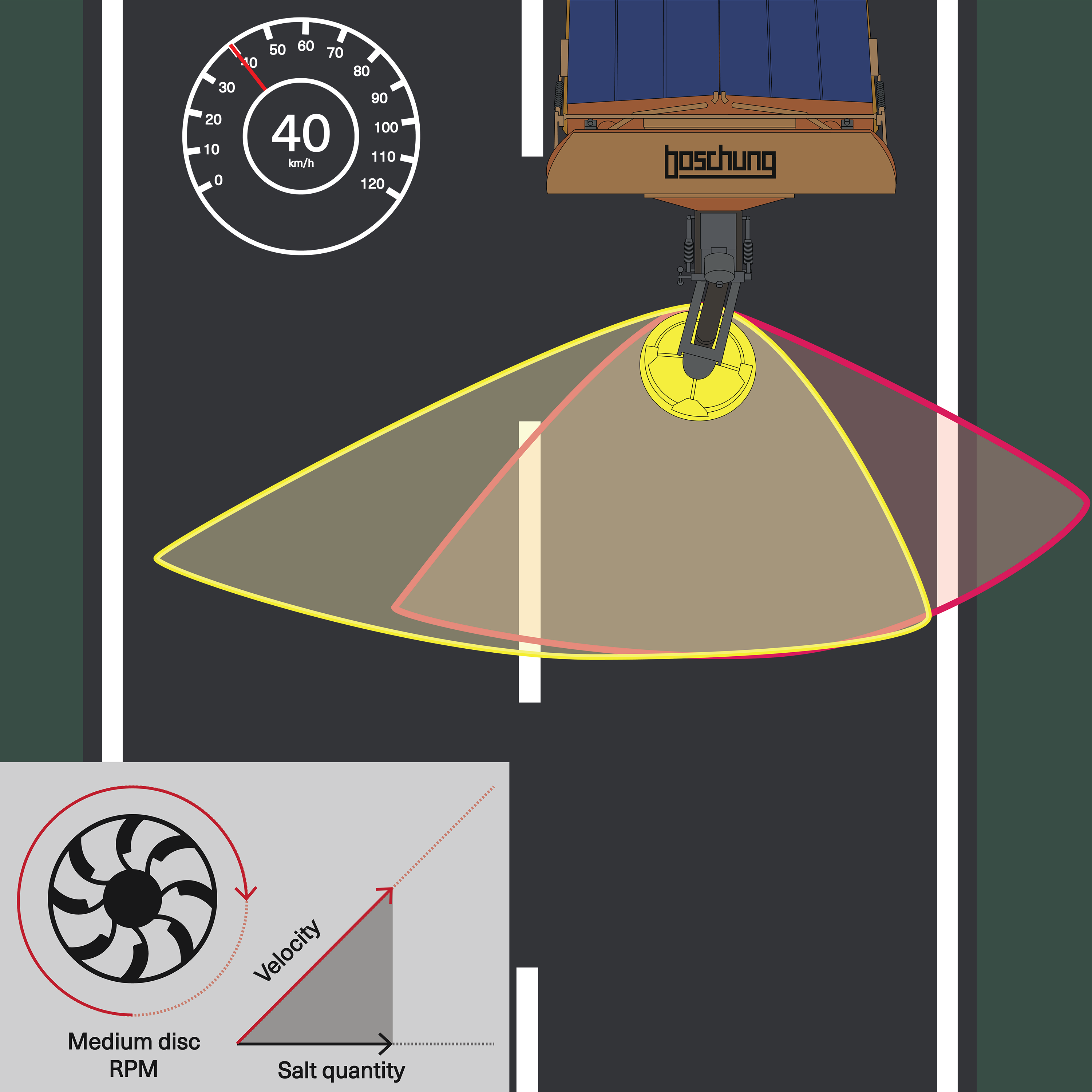

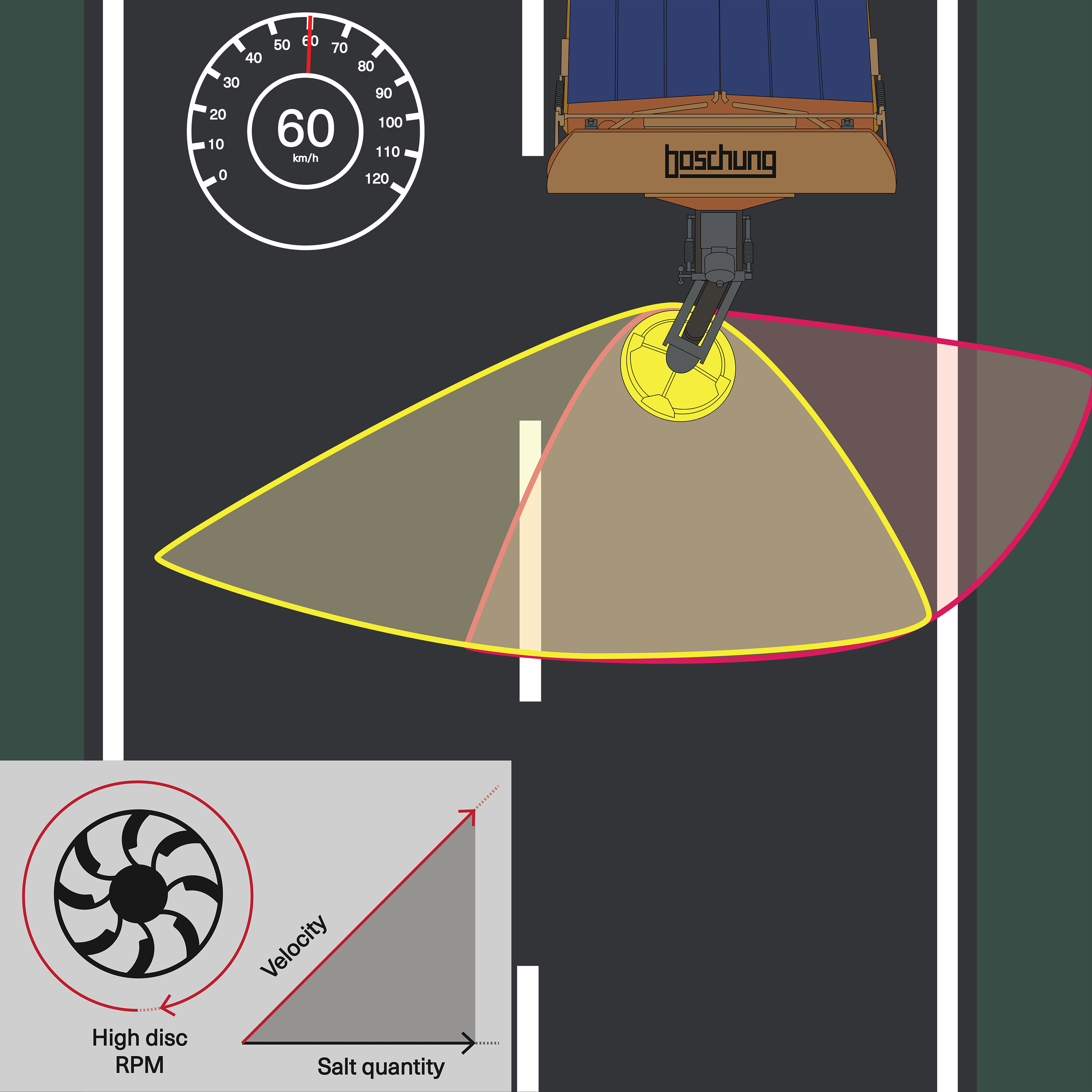

Because differences in road conditions, changes in velocity, spreading width and spreading density must all be taken into consideration to achieve the perfect de-icing, IMS gives you an automated system to achieve the perfect spreading regardless of the conditions. The driver can focus onto traffic while the intelligent spreading technology takes care of achieving the perfect de-icing job.

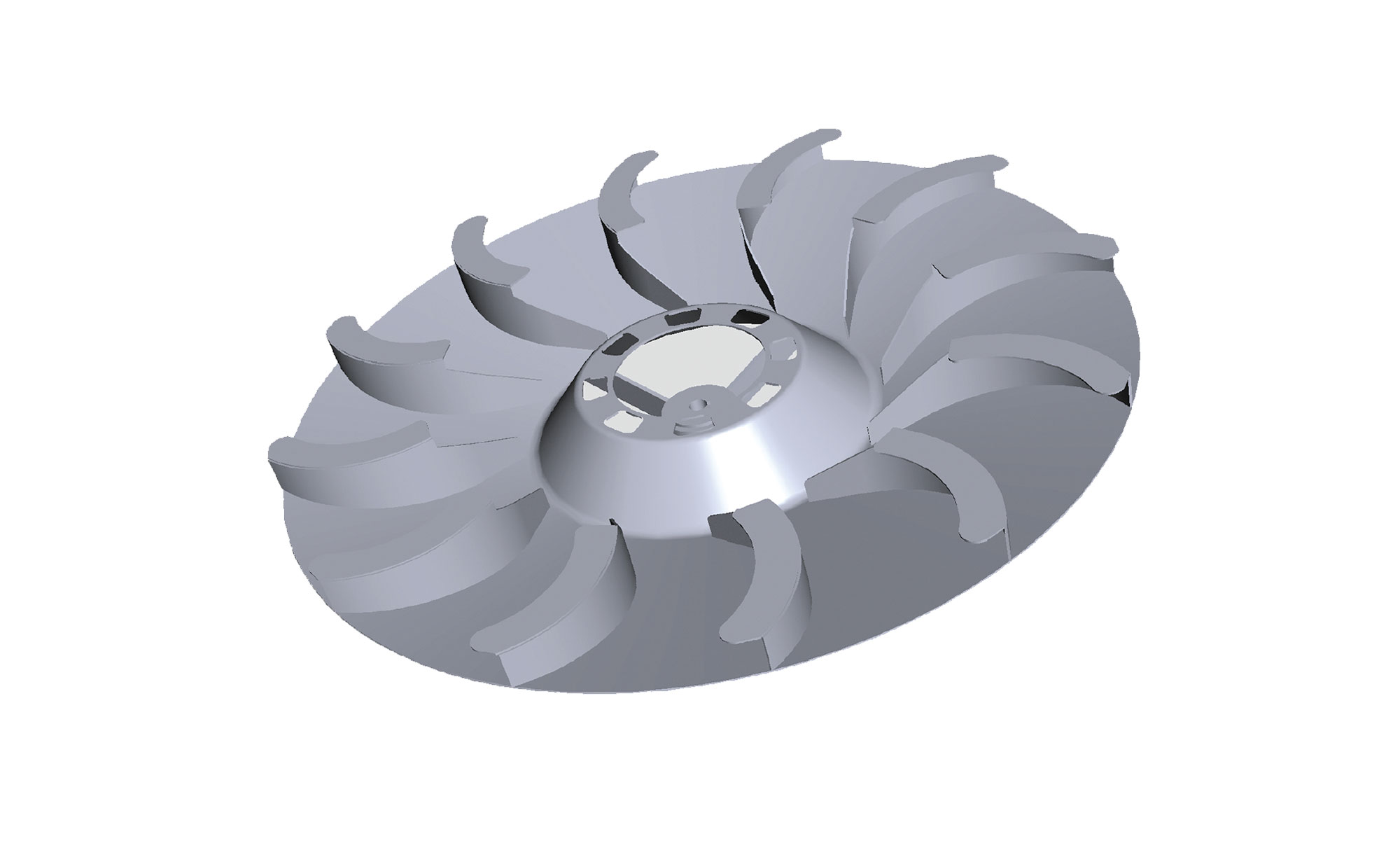

The automatic spreading width stabilization ASBS® compensates velocity by automatically adapting the rpm of the spinner disc.

The automatic distributor head adjustment ASN® assures a uniform spreading pattern regardless of the velocity automatically and in a fraction of milli-seconds.

Whether you are spreading while accelerating, doing high speed spreading and spreading on windy roads, the Boschung IMS will offer the most precise results ever measured.

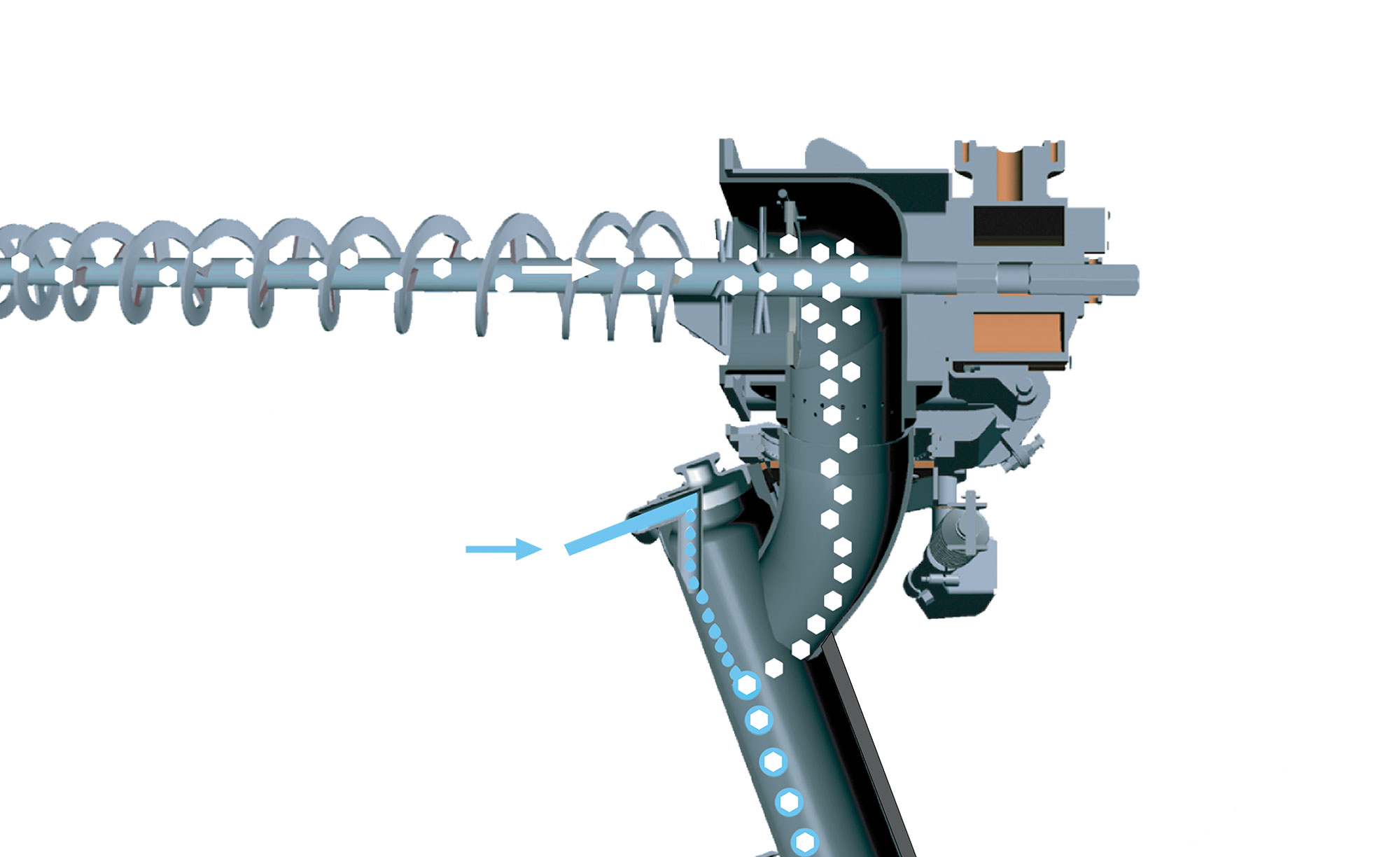

A constant feeding flow is ensured with the frequency overlaid auger rotation. Intermediate ridges and agitator fingers guarentee a perfectly relaxed salt and avoids all types of clusters.

The feeding is even at any hopper filling stage.

The integrated frequency controlled conveyor belt guarentees a constant feeding flow regardless of the density. The dosage sliders cut salt chunks to ensure a perfectly homogenous salt.

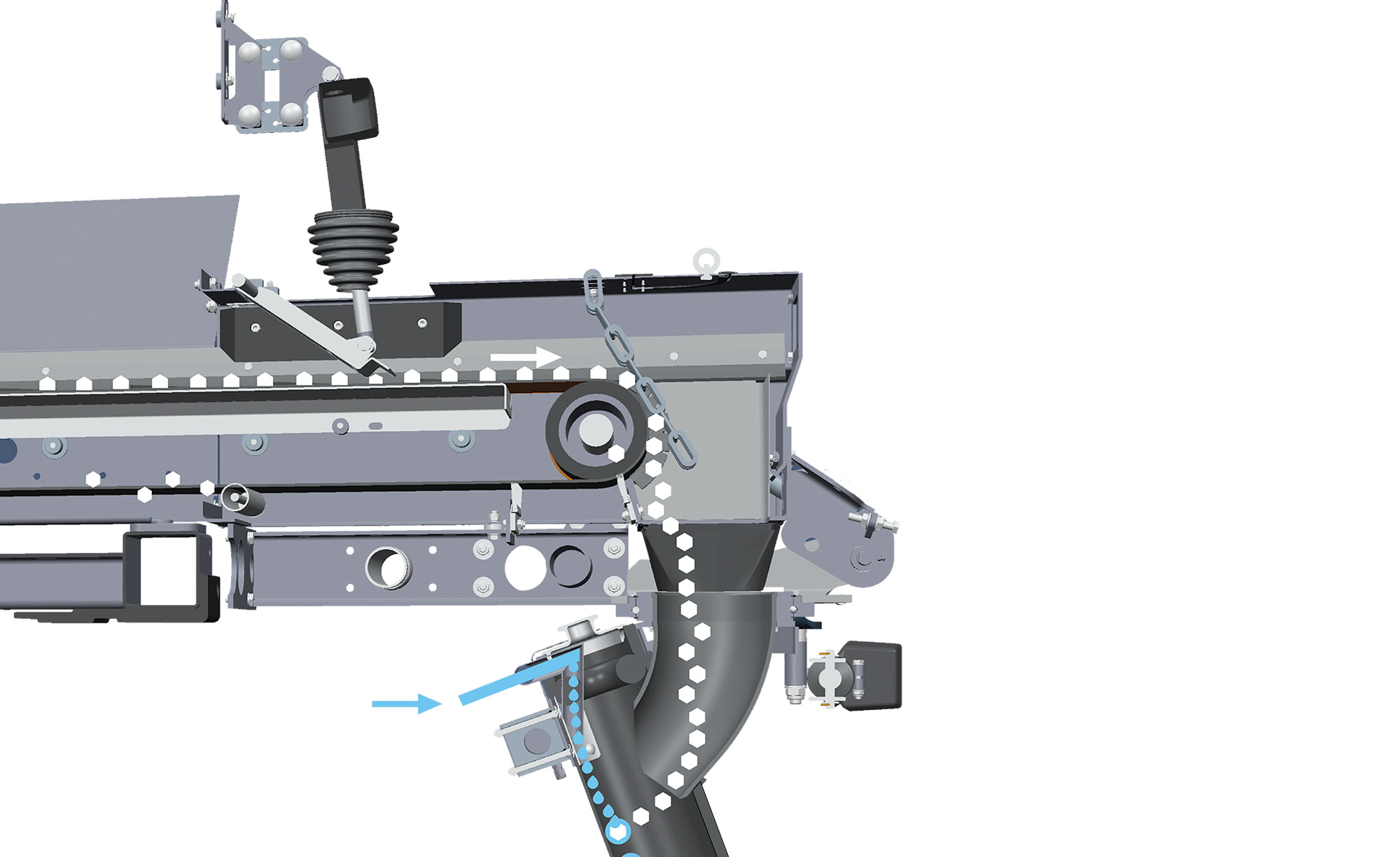

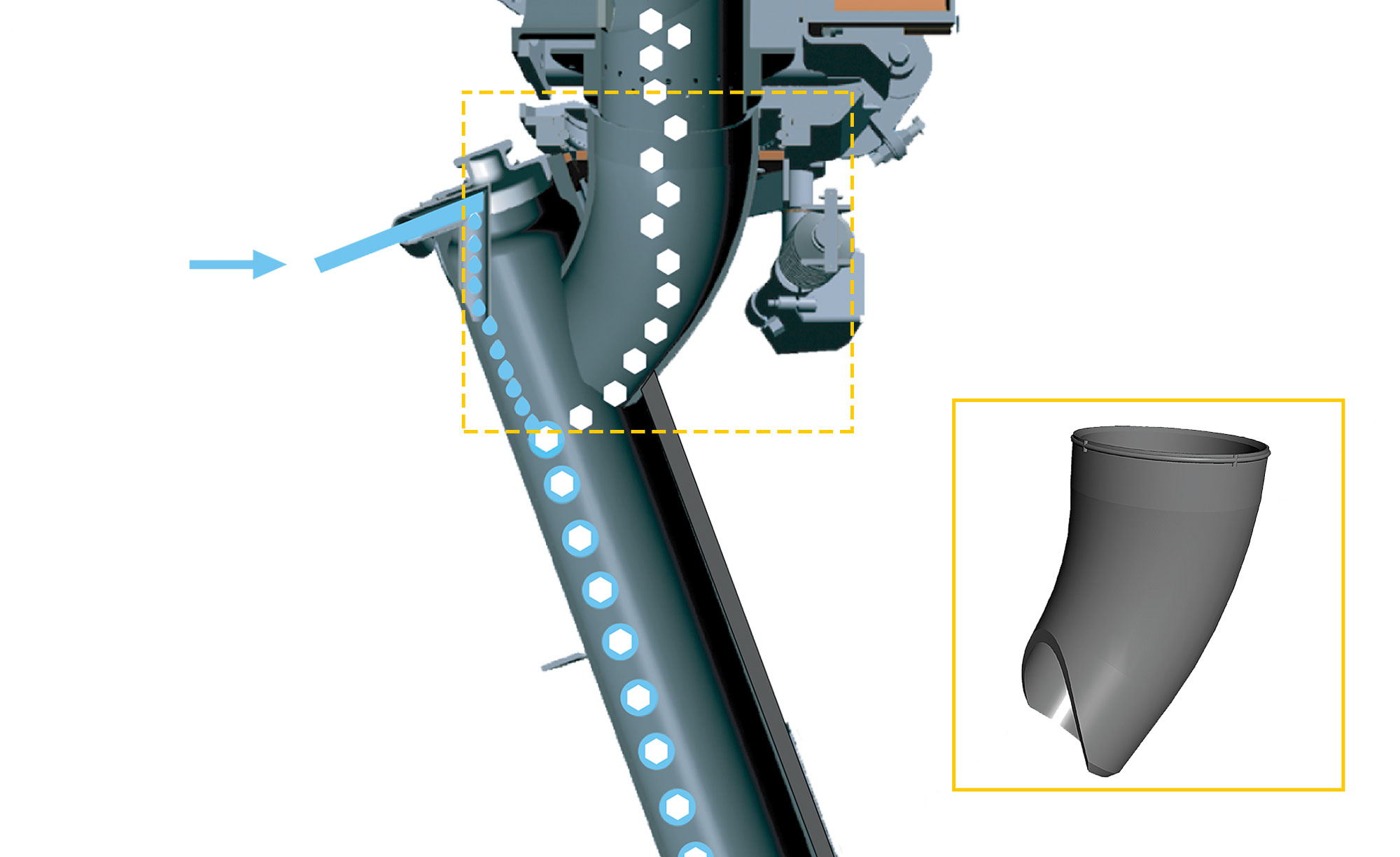

By opposing the flow direction of the salt and brine at contact, the elbow tube creates the perfect condition for a perfect mixture. The feeding towards the falling tube is ensured constentaly regardless of the distribution head position.

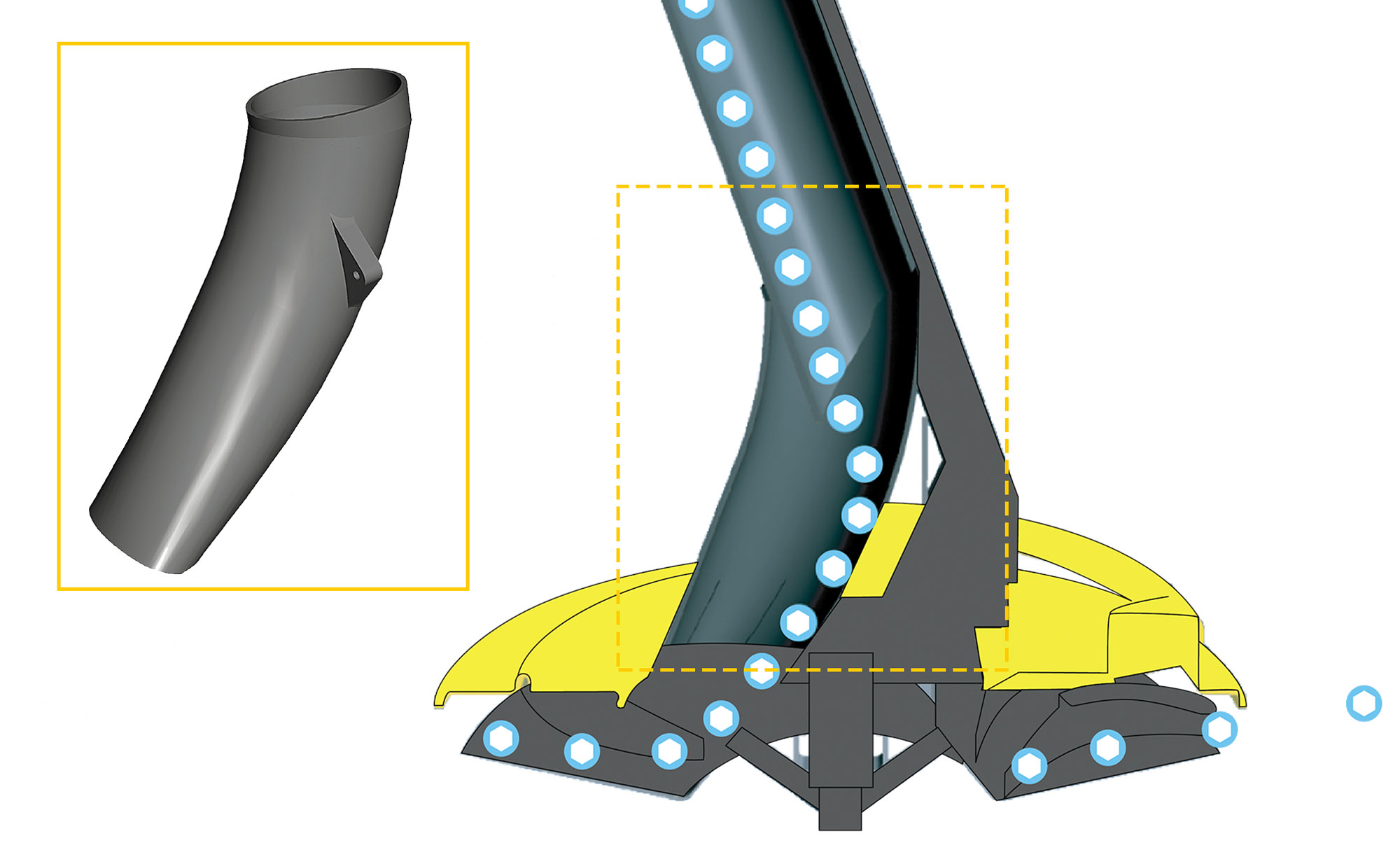

The specially engineered mouth piece directs the mixtured at the center of the spinner disk with a defined impact position. The result is an ideal lateral distribution of the salt/brine blend.

The elaborated geometry of the spinner disc along with its blades are specially designed following the flow of the spinner itself to allow consistancy and perfection during spreading.

The state-of-the-art engineering of the OptiWet® concept also includes the spreader direction adjustment via a slewing ring where the dry salt is falling into the elbow tube. This development ensures the direction of the mixture isn't changed and that the lateral distribution can be done at any position.

Salt

Brine

The result of the automatic FS-Adaptiv® is a perfect mixture for a perfect spreading regardless of the salt density

Lower density of salt requires more brine for a better adhesion

Higher density of salt requires less brine for a higher thawing action

The V-shaped design of the salt compartment of the IMS is specially built to optimize the feeding of the salt. On both sides of the compartment, are the brine tank used for the FS-Adaptiv®.

Years of experience with the de-icing of traffic surfaces have led us to one conclusion: prevention of the formation of ice is only efficient with a fully liquid solution. A 100% solution of brine is spread on the surface before the freezing occures, the solution will stick to the ground until temperature drops, evaporating the water and leaving on the surface the small particle of salt to prevent the formation of ice. Today with the patented Boschung FlexiWet®, install the flexible bag directly into your salt tank and use the same spreader adapted to all winter requirments.

Save

thawing agent using the ThermoMAT

Weather conditions can change extremely fast. Adjusting the spreading density to the actual road surface condition while your are doing the job will allow you to save up to 30% thawing agent. The highly precise infrared sensor of the ThermoMAT measures the road surface temperature while spreading is happening. The high speed detection allow a quick reaction and automatic adjustment of the spreading density.

Available in various versions, with joystick, rotary knobs and more, the Vpad is a simplified interface controlling nearly every aspects of your spreading experience.

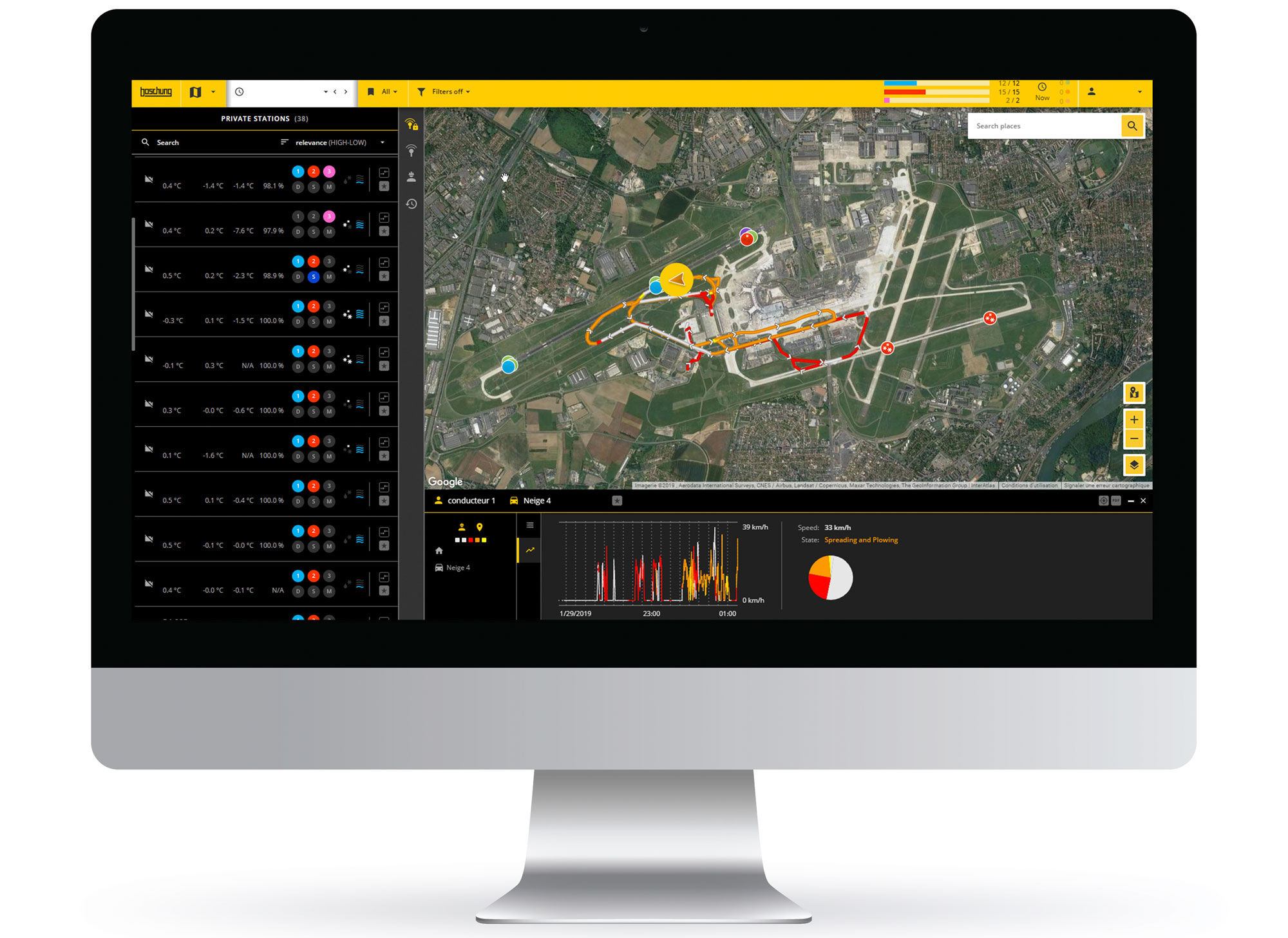

bVision, the Boschung Road and Runway Management platform unlocks a whole suite of surprising and integrated features for the ultimate connected work tool experience. With the refined engineering of Boschung and the limitless possibilities of today’s connectivity, bVision offers a better understanding of your spreading activities.

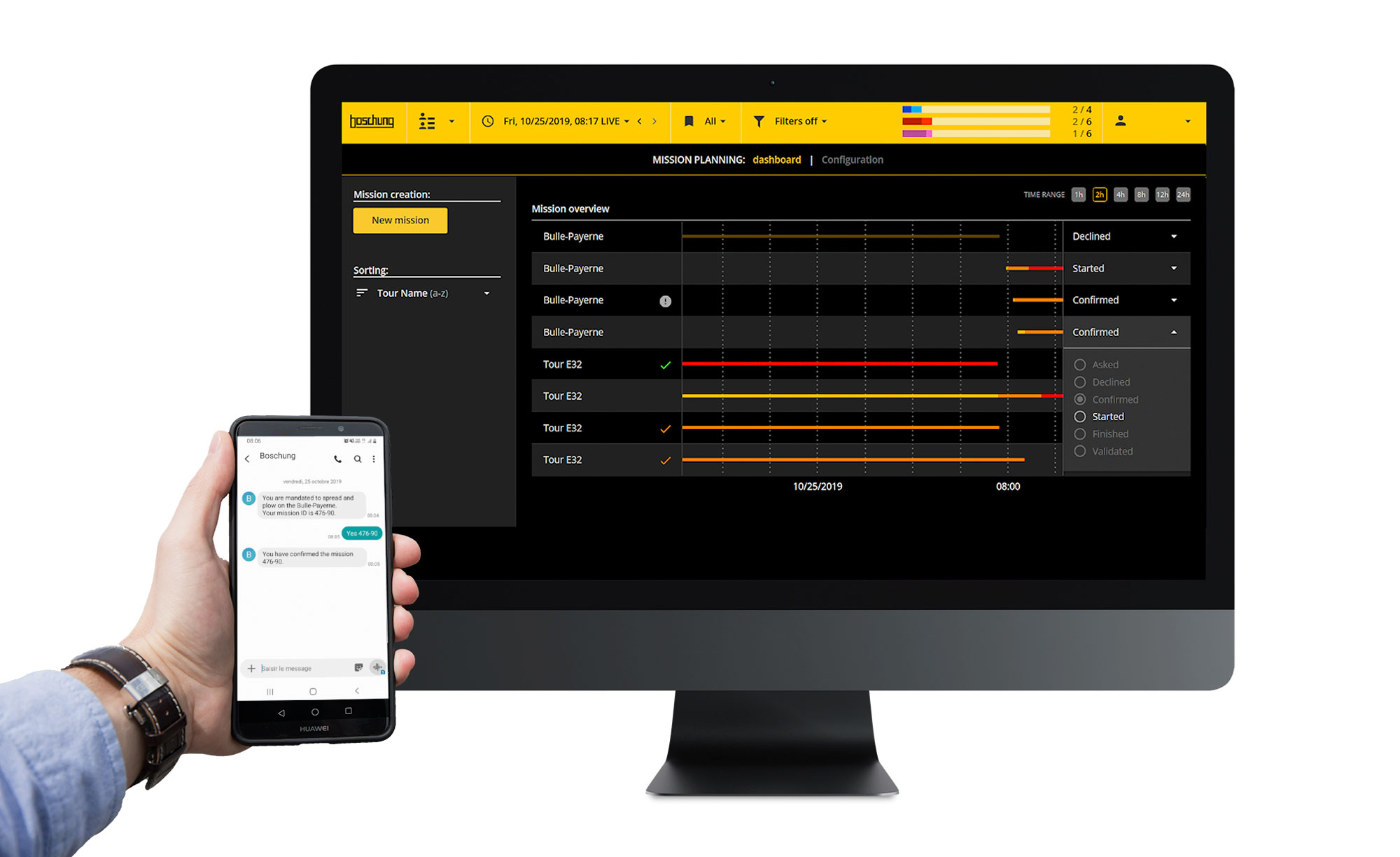

Ensure safety and fast reaction with the bVision Mission Planning. Missions are triggered as soon as the alarm comes in. Your team members recieve the mission directly on their phones via messages. Follow your missions status simultaneously directly from your computer.

Fully automate your spreading activities with BORRMA-Nav, GPS controlled spreading and ensure the most accurate spreading and dosage. Instructions are delivered directly on the Vpad with map and voice guidance. Let the driver focus onto traffic while BORRMA-Nav ensures the work is done with maximum efficiency.

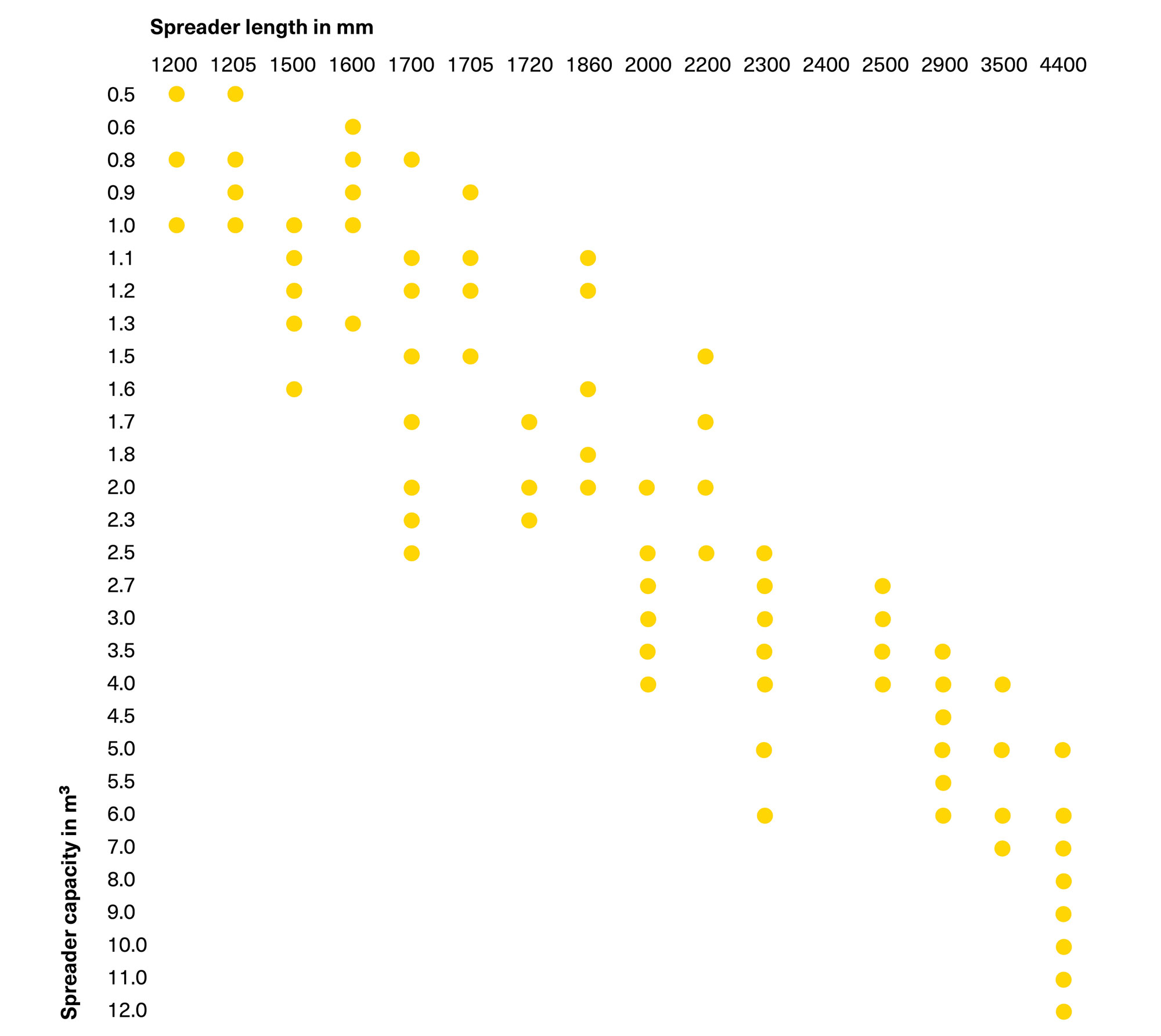

Perfection is achieved when everything is adjusted with one another. This is why the IMS series comes in various hopper capacities with different heights and lengths possibilities.

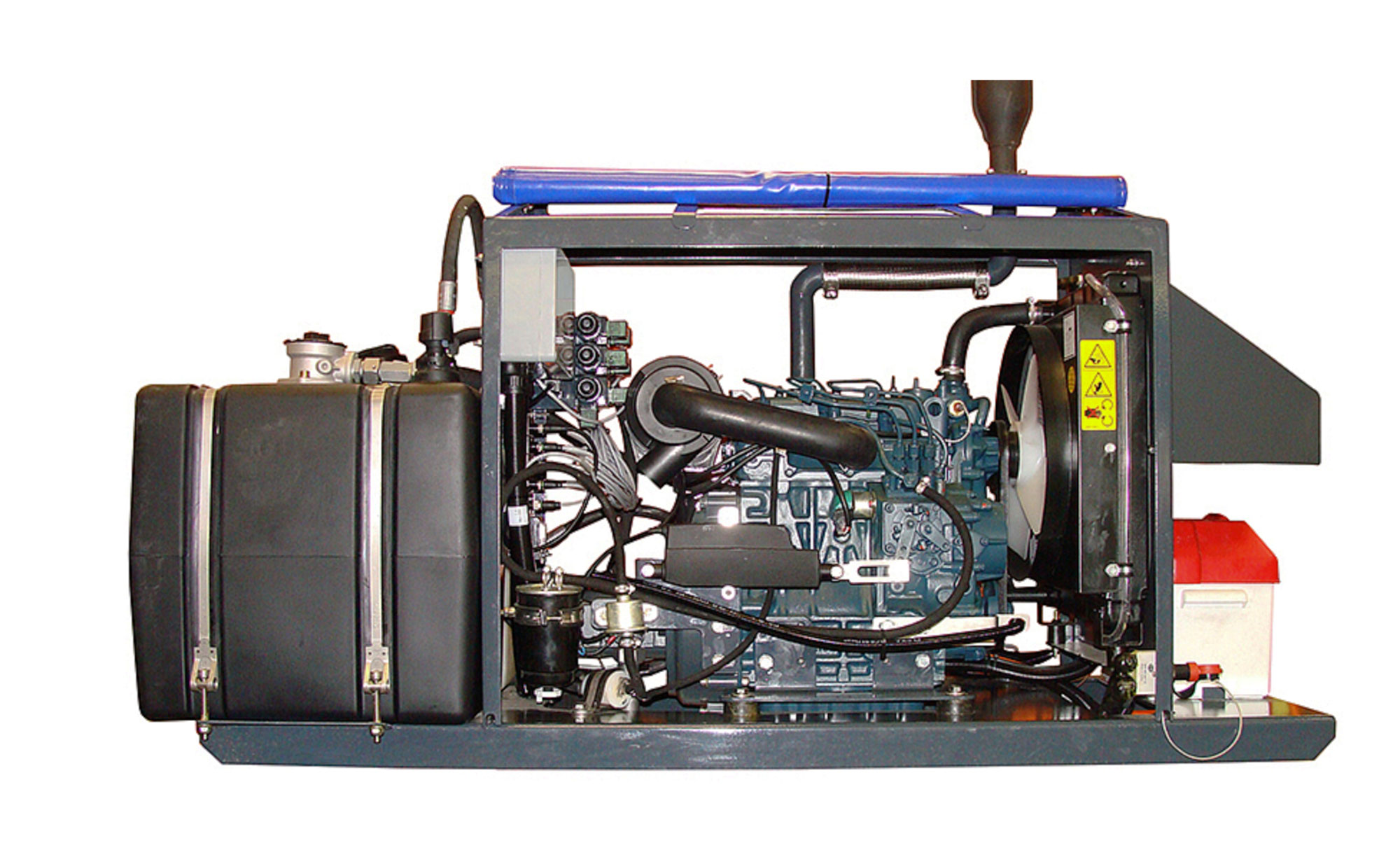

Equipped with the patented ECO control, the 3-cylinder Kubota diesel engine drive is a low-maintenance drive, easily accessible unit fittet into a dismountable frame.

The patented Eco engine control is an automatic and performance-depending control of the engine rpm. Connected directly to the Vpad it will adapt its power to your driving speed, spreading width and density, allowing up to 50% fuel saving meaning drastic CO2 emission cutback.

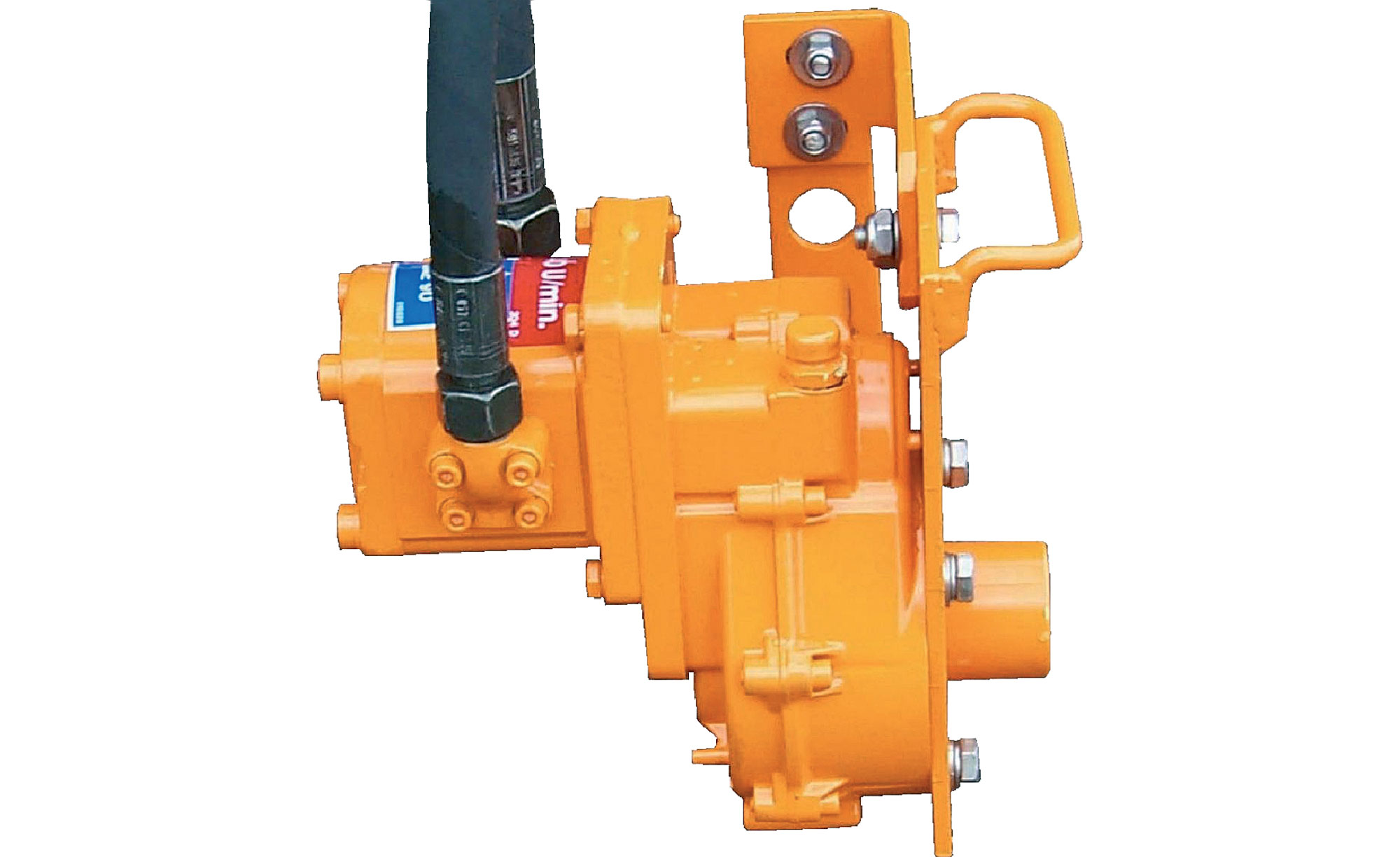

Trailer-spreader with integrated hydraulic drive, an economical and environmental friendly winter maintenance solution.

Receive advice about product specifications and find the right Boschung vehicle and equipment for your needs.